When it comes to ensuring smooth operation and longevity of wheels, whether on industrial equipment, automotive vehicles, or even office chairs, one often overlooked yet crucial component is caster grease. Properly maintaining the casters that support these wheels can significantly extend their lifespan and enhance their performance. In this comprehensive guide, we delve into everything you need to know about caster grease — from its importance to how to choose the right one for your application.

Understanding Casters and Their Importance

Casters are the wheel assemblies that enable smooth movement and rotation of objects. They come in various sizes and types, including swivel and rigid casters, each designed for specific applications ranging from heavy-duty industrial machinery to delicate furniture. Regardless of the application, all casters share a common need for lubrication to function optimally over time.

The Role of Caster Grease

Caster grease serves several essential purposes:

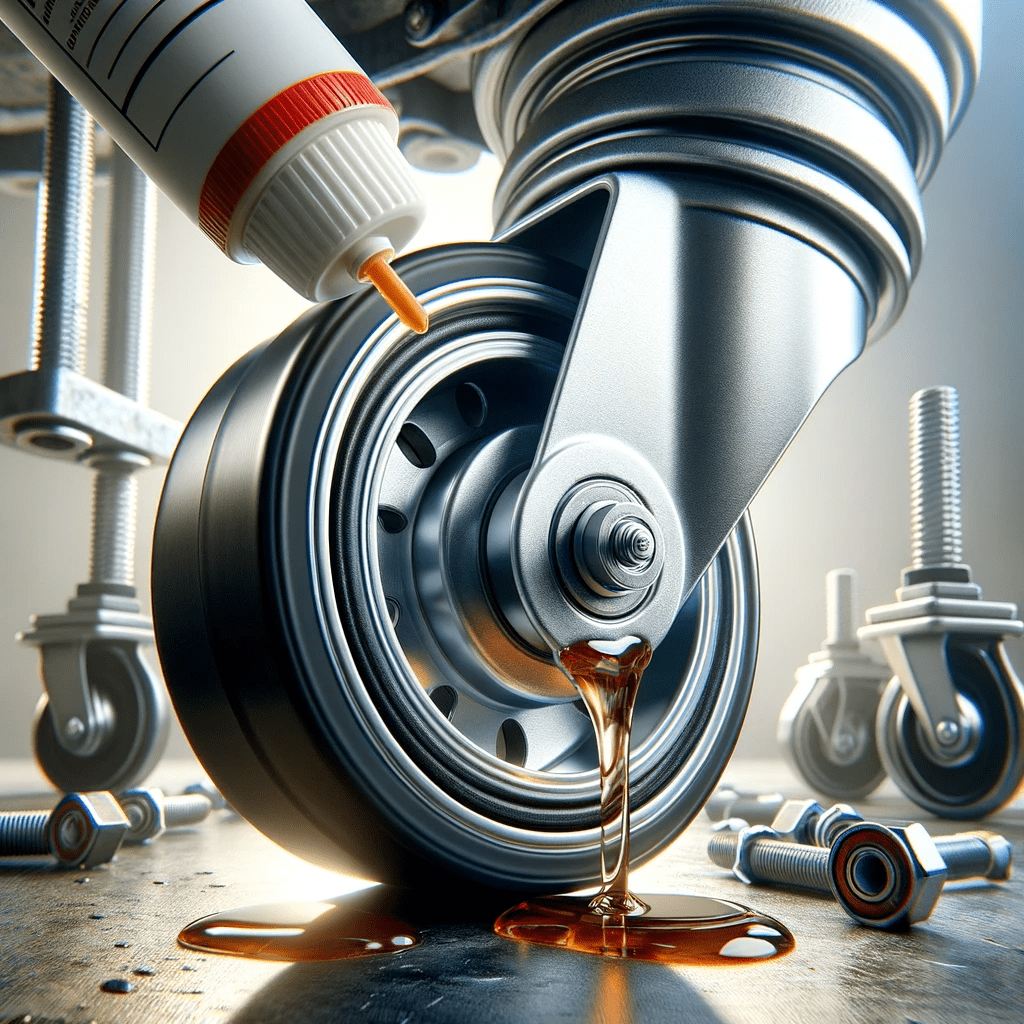

Reducing Friction and Wear: Applying grease to the caster bearings and swivel mechanism reduces friction between metal surfaces, thereby minimizing wear and tear. This is crucial for extending the caster’s operational life.

Protecting Against Corrosion: Grease acts as a barrier against moisture and contaminants that can cause rust and corrosion on metal surfaces. This protection is particularly important in environments with high humidity or exposure to chemicals.

Maintaining Smooth Movement: Properly lubricated casters move more smoothly, which not only improves maneuverability but also reduces the effort required to push or pull objects.

Choosing the Right Caster Grease

Selecting the appropriate caster grease depends on several factors:

Application Environment: Consider whether the casters will operate indoors or outdoors, in wet or dry conditions, and if they will be exposed to extreme temperatures or chemicals.

Load Capacity: Heavy-duty applications require grease that can withstand higher pressures and loads without breaking down.

Compatibility: Ensure the grease is compatible with the materials used in the caster components, such as metal bearings and synthetic seals.

Application and Maintenance Tips

To maximize the benefits of caster grease:

Clean Before Applying: Thoroughly clean old grease and dirt from the caster components before applying new grease.

- Apply Sparingly: Over-greasing can attract more dirt and debris, leading to accelerated wear. Apply grease in moderate amounts.

- Regular Maintenance: Schedule regular inspections and re-greasing intervals based on the manufacturer’s recommendations and usage conditions.

Popular Types of Caster Grease

Several types of grease are commonly used for casters:

- Multi-Purpose Lithium Grease: Suitable for general-purpose applications and offers good water resistance.

- High-Temperature Grease: Designed to withstand elevated temperatures, ideal for ovens, kilns, or automotive applications.

- Synthetic Grease: Provides enhanced protection against corrosion and oxidation, suitable for harsh environments.

Caster grease plays a vital role in maintaining the performance and longevity of wheels across various applications. By understanding its importance, choosing the right type, and applying it correctly, you can ensure that your casters operate smoothly and efficiently for years to come. Whether you’re managing a fleet of industrial carts or simply want to improve the comfort of your office chair, investing in quality caster grease is a small step with significant long-term benefits.

Remember, a well-greased caster not only rolls smoothly but also supports the reliability and efficiency of your equipment — a testament to the impact of proper maintenance in every rolling revolution.